Perforated sheet Buy from Europe's largest perforated sheet warehouse

With an impressive stock of over 250,000 perforated sheets and a diverse range of more than 1,300 different types, JAERA offers the most extensive range of perforated sheets and perforated plates in the whole of Europe. Discover our huge product selection of high-quality perforated sheets made of stainless steel, steel or aluminum here. Choose from a wide range of different perforations, hole types, materials or dimensions - Perforated sheet can also be made to measure.

You want to buy perforated metal sheets ? Put your trust in our over 40 years of expertise, because Perforated sheet is what you buy from JAERA!

Overview

Three steps to your Perforated sheet

01

01 Find product

Find product with the filter function.02

02 Shopping cart

Add product Cart03

03 Inquiry

Fill in the inquiry form. We will process your request within a few minutes.

Perforated Sheet Product Filter

Material

Thickness [mm]

Hole type

Perforation-pitch

Dimension [mm]

Throughput

0,00 - 81,00

Results 1 - 20 of 1355 are displayed

| Material | ALMG1 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | HT = Hexagonal perforation (hexagonal perforation) |

| Perforation-pitch | 2-2,5 |

| Weight | 19,6 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 0,8 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 5-8 |

| Weight | 2,79 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 10-14 |

| Weight | 2,64 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 10-15 |

| Weight | 3 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 5-8 |

| Weight | 3,29 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 8-12 |

| Weight | 3 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 3-5 |

| Weight | 3,64 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 4-6 |

| Weight | 3,22 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 5-8 |

| Weight | 3,49 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 8-12 |

| Weight | 3,22 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1250 |

| Length | 2500 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 2,5-4 |

| Weight | 5,45 |

| Dimension | 1250 x 2500 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1250 |

| Length | 2500 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 3-5 |

| Weight | 5,68 |

| Dimension | 1250 x 2500 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1250 |

| Length | 2500 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 4-6 |

| Weight | 5,04 |

| Dimension | 1250 x 2500 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1250 |

| Length | 2500 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 5-8 |

| Weight | 5,45 |

| Dimension | 1250 x 2500 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1500 |

| Length | 3000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 3-5 |

| Weight | 8,18 |

| Dimension | 1500 x 3000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1500 |

| Length | 3000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 4-6 |

| Weight | 7,25 |

| Dimension | 1500 x 3000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1 |

| Wide | 1500 |

| Length | 3000 |

| Hole type | RT = round perforation in staggered rows |

| Perforation-pitch | 5-8 |

| Weight | 7,85 |

| Dimension | 1500 x 3000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1,5 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 10-14 |

| Weight | 3,97 |

| Dimension | 1000 x 2000 |

| Material | ALMG3 |

|---|---|

| Thickness | 1,5 |

| Wide | 1000 |

| Length | 2000 |

| Hole type | CU = square holes in straight rows |

| Perforation-pitch | 10-15 |

| Weight | 4,5 |

| Dimension | 1000 x 2000 |

Why should you buy perforated sheet from JAERA?

Perforated metal sheets are purchased from JAERA. We are your reliable supplier of Perforated sheet since 1982. Your advantages at JAERA:

- Largest range of perforated plates in Europe

- Experience from over 40 years perforated sheet-trade

- Fast processing of your requests

- Highest quality standards

- Short delivery time, NEXTDAY delivery possible

- No minimum purchase

- Comprehensive service and individual customer advice

- Further processing service & fabrications as requested

Perforated sheet - Sheet thicknesses & dimensions

At JAERA, we not only want to offer you first-class quality, but also a wide range of products. That's why we stock a large selection of Perforated sheet and anti-slip perforated sheets, including standard and special dimensions and perforations that are available directly from stock. You can find our huge range of different perforated sheets in the product filter or in our product catalog.

Theoretically, perforated sheet can be manufactured in a variety of individual sizes. At JAERA, we offer the following dimensions and material thicknesses:

Plate Thickness Perforated Plate:

- 0.4 mm

- 0.5 mm

- 0.6 mm

- 0.75 mm

- 0.8 mm

- 1.0 mm

- 1.5 mm

Perforated Plate Dimensions:

- 1,000 x 2,000 mm

- 1,250 x 2,500 mm

- 1,500 x 3,000 mm

- 2.0 mm

- 2.5 mm

- 3.0 mm

- 4.0 mm

- 5.0 mm

- 8.0 mm

- 10.0 mm

Perforated Metal Sheet - Hole Types

Perforated sheets can be provided with a wide variety of hole types, which differ depending on the intended use, be it functional or decorative. Here you can see an overview of the types of holes we have on offer at JAERA.

- Round Perforation: Evenly spaced, round holes in various diameters. They can be produced in straight or staggered rows.

- Square Perforation: Evenly spaced, square holes with clear edges. They can be made in straight or staggered rows and offer uniform permeability in all directions.

- Oblong perforation: Elongated holes, often with rounded corners. They enable a specific permeability direction.

- Hexagonal Holes: Hexagonal, honeycomb-shaped holes. They offer high stability with low material consumption.

- Slotted Perforation: Narrow, elongated holes, similar to a slot. They allow high permeability in one direction.

- Creative Perforation/Decorative Perforation: Can be produced in specific shapes and arrangements according to customer requirements. Depending on the design specification, they often include combinations of the above shapes or completely unique designs.

JAERA further Processing Service for Perforated Sheets

Do you have individual wishes? We are happy to implement them in our finishing service.

We cut your perforated sheet to size as required. We estimate a delivery time of around one week for cutting to size.

Cutting up to 2,400 mm cutting length:

- Cut to size perforated sheet steel/galvanized: up to a material thickness of 4.0 mm

- Cut to size perforated metal sheet Stainless steel: up to a material thickness of 3.0 mm

- Cut to size perforated sheet Aluminum: up to a material thickness of 4.0 mm

Cutting up to 3,000 mm cutting length:

- Cut to size perforated sheet Steel/galvanized: up to a material thickness of 3.0 mm

- Cut to size Perforated sheet stainless steel: up to a material thickness of 2.0 mm

- Cut to size perforated sheet Aluminum: up to a material thickness of 3.0 mm

You are welcome to enquire about which further processing options can be implemented for your product. Please use our contact form or make your request by telephone.

Perforated Metal Sheets - all Information

Here you will find all the important information about perforated sheets. If you have any questions about your order or questions about individual products, please contact us using the contact form.

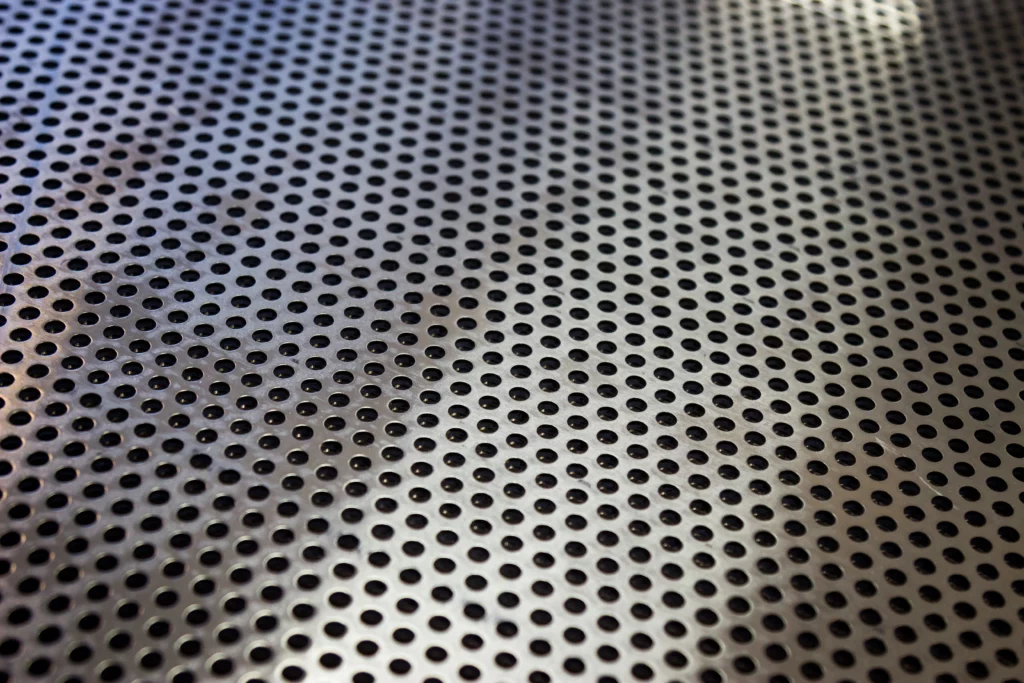

What are perforated sheets?

Perforated metal sheets are actually correctly referred to as perforated plates in accordance with DIN 24041. These are metal plates in which uniform holes are punched, lasered, pressed or rolled. There are different types of holes, such as slotted holes, square holes or round holes, which can have different hole sizes.

Perforated sheet are available in several materials, most commonly stainless steel, steel or aluminum. Thanks to the combination of high resistance and aesthetic appearance, perforated sheet is used in industry as well as in creative work and crafts.

What areas of application are there for perforated sheet?

Perforated metal sheets have versatile applications, whether as decorative elements in creative crafts or with technical functions in industry. Perforated plates are suitable, for example, as covers, protective grids, linings, filters or screens. Here you will find some of the many possible uses of perforated plates:

Industry & Technology:

- Building services: ventilation systems, heating installations and facade cladding.

- Mechanical engineering: component of machine cladding or parts.

- Automotive industry: ventilation grilles, radiator grilles and other body elements.

- Electrical industry: As protective covers and housings for electronic components.

- Household appliances: use in products such as washing machines or dryers.

- Food processing: As sieves or filters for various production processes.

- Metalworking industry: For filtering, sorting and separating materials; in the production of metal products or as an insert in certain manufacturing processes.

Craft & creative work

- Gardening and landscaping: as garden gates, garden fences or decorative elements in gardens.

- Furniture design: for pieces of furniture, such as benches, shelving structures or tables.

- House & apartment: balcony railings, stair railings or bicycle racks

- Art projects: For sculptures, wall decorations or other creative applications.

- Craft DIY projects: For individual solutions, e.g. lampshades, shelves or partitions.

What are the advantages of perforated sheet?

Perforated metal sheets are valued in various industries and applications for their versatile properties and advantages. They combine the strength and durability of metal sheets with the ability to create individual designs and functions through different perforations and material selection. This makes them in high demand for both technical and design applications.

You want to buy perforated sheet ? Convince yourself of the advantages of our Perforated sheet:

- Versatility: Adaptable to different applications through different hole sizes, shapes and arrangements.

- Weight reduction: Due to the perforated structure, they are often lighter than solid sheets with similar strength.

- Permeability: Allow the flow of air, fluids and light, making them ideal for ventilation, filtration and lighting applications.

- Aesthetics: with different designs and surface treatments, they offer visual appeal for decorative purposes.

- Cost-effectiveness: Often less expensive to manufacture and install compared to other material solutions.

- Robustness: Despite the perforated structure, they maintain high mechanical strength and durability.

- Heat dissipation: In technical applications, they can contribute to improved heat dissipation.

- Good workability: Perforated sheet is easy to cut, shape and customize, allowing easy assembly and adaptation to specific requirements.

- Corrosion resistance: Many Perforated sheet, especially those made of stainless steel or other corrosion-resistant materials, provide excellent protection against rust and corrosion, which extends their service life.

- Hygiene: Perforated plates are easy to clean and can be kept sterile. Therefore, they can be used in sensitive areas with high hygiene standards.

How is perforated sheet produced?

Perforated plates are manufactured as semi-finished products, i.e. as prefabricated raw material for further processing. Their production begins with solid metal plates that have been shaped into the desired form by various processes. The plates are then given their holes by punching, pressing, rolling or laser cutting. Other processes include flame cutting or waterjet cutting.

Thanks to modern machines such as wide presses, automatic punching machines or special lasers, precise hole patterns are created in different shapes and sizes, either in straight or staggered rows. Depending on the area of application, various materials such as stainless steel, aluminum or steel can be used. This processing step can be followed by finishing and further processing steps that give the Perforated sheet its final properties and surface finish. These include

- Forming processes such as bending, folding, profiling.

- Cutting to size by punching or lasering

- Surface treatment by brushing, sandblasting or polishing

- Riveting, screwing, welding or soldering

- Coating and corrosion protection

What materials are perforated sheets available in?

Perforated plates are available in a wide variety of materials, which differ depending on the intended use. The most commonly used are Perforated sheet in stainless steel, steel or aluminum.

- Stainless steel: Perforated sheet made of stainless steel are rustproof, resistant to many chemicals, hygienic and durable. That is why they are used, for example, in chemical processing, outdoors or in food processing.

- Steel: Perforated sheet made of steel are very robust, versatile, relatively inexpensive and can be protected against corrosion by coatings or galvanizing. Steel is often used in mechanical engineering or construction.

- Aluminum: Perforated sheets made of aluminum are lightweight, corrosion-resistant and easy to shape, and they also offer high thermal and electrical conductivity. Aluminum is therefore used, for example, in vehicle construction or in the electronics sector.

- Copper: Excellent electrical conductivity, corrosion resistance and it provides an aesthetic luster. Uses include the electrical industry or decorative applications.

- Brass: Non-magnetic, easy to work with and offers a striking gold-like appearance. Therefore, it is suitable for decorative work, fittings or in the electrical industry.

What are perforation, culvert and throughput for perforated plates?

- The perforation indicates the hole diameter.

- The division indicates the distance from center to center of adjacent holes. It defines how close the holes are arranged to each other and thus influences the stability of the sheet and the amount of Material between the holes.

- The throughput designates the percentage of the open area of a perforated plate in relation to the total area. This can be calculated from the perforation and the pitch. A high Open area means that a large area of the sheet is open (i.e. has many and/or large holes), while a low Open area indicates a denser pattern with less open area. This value is crucial for functions such as ventilation, filtration or light transmission.

Example: A hole pitch of 2-3 means that the hole has a diameter of 2.0 mm and the distance from the center of one hole to the other is 3.0 mm.

Sonic

2024-01-12

Schnelle Lieferung und Material top.

Marc Culas

2023-11-28

Sehr kompetente Beratung - hier wird auf die individuellen Bedürfnisse wirklich eingegangen. Danke & weiter so!

Vicky Moschny

2023-11-13

Absolut Empfehlenswert! Freundliches und kompetentes Personal. Gute Qualität, hervoragender Service und Preis-Leistungsverhältnis. Pünktliche Lieferungen. Vielen Dank und herzliche Grüße an JAERA!

Oscar Casares Solera

2023-11-02

Diese Firma ist einfach herausragend! Ihre Produkte/Dienstleistungen haben meine Erwartungen übertroffen, und die Qualität ist wirklich bemerkenswert. Der Kundenservice ist stets freundlich und äußerst hilfsbereit. Ich kann diese Firma uneingeschränkt empfehlen und werde mit Sicherheit weiterhin ihre Leistungen in Anspruch nehmen. Fünf Sterne sind definitiv verdient!

Andrea S

2023-11-01

Super kompetente Beratung, schnelle Lieferung und erstklassige Qualität. Das Alles zu fairen Preisen.

Jederzeit wieder und sehr zu empfehlen.

Thomas Schäfer

2023-10-31

Haben für unseren Balkon ein Lochblech benötigt, haben gute Beratung und passendes Blech schnell erhalten, empfehlenswert.

Nicolas Holle

2023-10-30

Für meinen Brennstoffhandel (www.holle-premium-holzbrennstoffe.de) habe ich zum Lagerbau von Pellets und Holzbriketts Lochbleche und Gitter benötigt.Der Service, die Lieferung und der Kontakt war hervorragend. Immer wieder gerne. Diese Firma ist zu empfehlen und meine erste Anlaufadresse wenn ich wieder Bleche benötige.

Mariusz Kantor

2023-10-30

Freundlicher Kontakt und Lösungsorientiertes arbeiten.

Google Overall rating 5.0 out of 5 based on 51 reviews