Expanded metal buy from JAERA

JAERA offers you a large selection of expanded metal grilles made of various materials: Expanded metal Stainless steel, Expanded metal steel, Expanded metal aluminium, Expanded metal galvanized and more. Discover our wide range of different specifications and mesh shapes. Benefit from our fast processing of product inquiries and short delivery times.

You want to buyExpanded metal ? Put your trust in JAERA, your experienced specialist for grating solutions with more than 40 years of expertise!

Overview

Three steps to your expanded metal mesh

01

01 Find product

Find product with the filter function.02

02 Shopping cart

Add product Cart03

03 Inquiry

Fill in the inquiry form. We will process your request within a few minutes.

Expanded metal Product filter

Material

Mesh form

Specification

Mesh length x mesh width x web width x basic thickness

Throughput

17,00 - 82,00

Dimension [mm]

Results 1 - 20 of 66 are displayed

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 10 x 5 x 2 x 0.8 |

| Weight | 3,4 |

| Dimension | 1000 x 2000 |

| Throughput | 20 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 110 x 42 x 10 x 2 |

| Weight | 5,3 |

| Dimension | 1000 x 2000 |

| Throughput | 52,4 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 6,5 x 1 x 1 |

| Weight | 1,6 |

| Dimension | 1000 x 2000 |

| Throughput | 69 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 8 x 1.5 x 1 |

| Weight | 22 |

| Dimension | 1000 x 2000 |

| Throughput | 6,25 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 3,2 |

| Dimension | 1000 x 2000 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 31 |

| Dimension | 1000 x 2000 |

| Throughput | 61 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 6 x 3 x 1 x 0.5 |

| Weight | 1,7 |

| Dimension | 1000 x 2000 |

| Throughput | 35 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Square mesh |

| Specification | M 10 |

| Weight | 18 |

| Dimension | 1250 x 2500 |

| Throughput | 75 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Square mesh |

| Specification | M 30 |

| Weight | 2,7 |

| Dimension | 1250 x 2500 |

| Throughput | 82 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 10 x 5 x 1.5 x 1 |

| Weight | 5,3 |

| Dimension | 1250 x 2500 |

| Throughput | 37 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 16 x 8 x 1.5 x 1 |

| Weight | 3,3 |

| Dimension | 1250 x 2500 |

| Throughput | 6,25 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 20 x 10 x 2 x 1.5 |

| Weight | 5 |

| Dimension | 1250 x 2500 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 5 |

| Dimension | 1250 x 2500 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 4,8 |

| Dimension | 1250 x 2500 |

| Throughput | 61 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 62 x 25 x 3 x 2 |

| Weight | 4,05 |

| Dimension | 1250 x 2500 |

| Throughput | 76 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 10 x 4.5 x 1 x 0.5 |

| Weight | 3,6 |

| Dimension | 1000 x 2000 |

| Throughput | 55 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 6,5 x 1 x 1 |

| Weight | 4,9 |

| Dimension | 1000 x 2000 |

| Throughput | 69 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 9,6 |

| Dimension | 1000 x 2000 |

| Throughput | 60 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 4 x 2.2 x 0.5 x 0.5 |

| Weight | 3,6 |

| Dimension | 1000 x 2000 |

| Throughput | 54 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 9,3 |

| Dimension | 1000 x 2000 |

| Throughput | 61 |

Why should you buy expanded metal mesh from JAERA?

JAERA is your specialist for Expanded metal. We have been providing high-quality grating solutions for industry since 1982. Your advantages with JAERA:

- Large range of different expanded metal meshes

- Experience from over 40 years of grille trading

- High customer satisfaction

- Fast processing of your requests

- Highest quality standards

- Short delivery time, NEXTDAY delivery possible

- No minimum purchase

- Comprehensive service and individual customer advice

- Further processing service & fabrications as requested

Expanded metal – Specifications, dimensions & material thicknesses

At JAERA, we always want to offer you a wide range of products of the best possible quality. That is why we have a wide range of expanded metal in various product specifications and dimensions in our program, which are available directly from stock.

Choosing the right product specification for your expanded metal depends on the intended use, which can vary greatly from façade design to machine protection. You should also consider individual requirements and personal preferences.

Our wide range of different expanded meshes can be found in the product filter or in our product catalogue.

Below you will find all the information on dimensions and specifications from our range:

Specifications

JAERA offers expanded metal mesh in over 80 different product specifications, including both standard and special mesh widths, mesh widths and bar widths. The mesh lengths of our Expanded metal range from 4.0 mm to 115.0 mm, for example. We offer mesh sizes from 2.2 mm to 42.0 mm. Please use our product filter to find the product with the correct product specifications.

Dimensions & material thicknesses

We offer expanded metal mesh in the following basic thicknesses and dimensions to suit your project:

Dimensions:

- 1,000 x 2,000 mm

- 1,250 x 2,500 mm

- 1,500 x 3,000 mm

- 2,000 x 3,000 mm

Basic thicknesses:

- 0.5 mm

- 0.8 mm

- 1.0 mm

- 1.5 mm

- 2.0 mm

- 3.0 mm

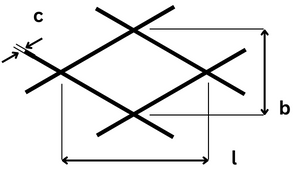

Geometry of expanded metal:

Mesh length (l): Distance from node to node in longitudinal direction in mm.

Mesh size/mesh width (b): Distance from node to node in transverse direction in mm.

Bar width (c): Width of the fixed metal bar in mm.

Expanded metal - Mesh shapes at JAERA

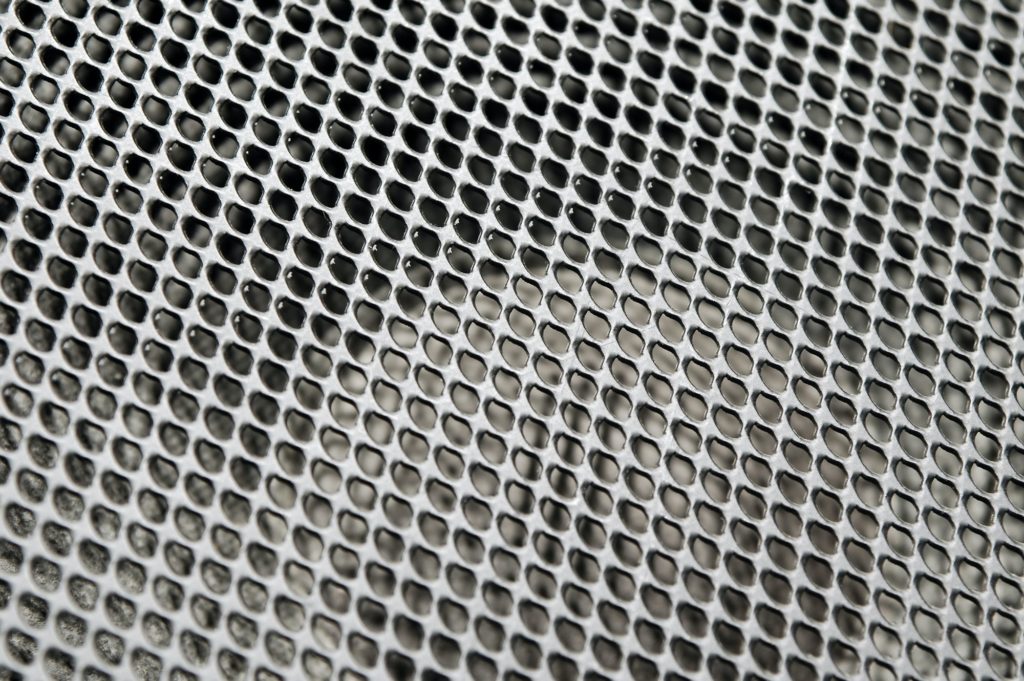

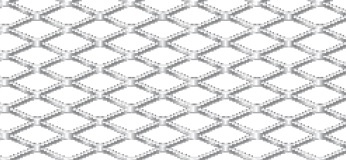

Thanks to their different mesh shapes, expanded metal meshes offer a wide range of design options that can be both functional and decorative in nature. Below we present the mesh shapes that we offer at JAERA:

- Diamond meshThe Diamond mesh, also known as diamond mesh, is characterized by its distinctive diamond-shaped and aesthetically pleasing openings. This shape offers high strength and is particularly suitable for applications where good stress distribution is required.

- Square mesh: The square mesh is characterized by uniformly shaped, square openings that provide a consistent and symmetrical appearance. This mesh shape is often used in applications where uniform load distribution and high permeability in all directions are required.

- Round mesh Round mesh are with circular openings, which are an attractive and versatile alternative to traditional mesh shapes. This mesh shape offers excellent permeability and is often used for decorative purposes as well as in applications. Expanded metal

JAERA further processing service

Do you have individual wishes? We are happy to implement them in our finishing service.

Cutting to size:

We cut your expanded metal to size as required. You can choose whether you want to cut through an open or closed mesh. We estimate a delivery time of around one week for cutting to size.

- Cutting to size up to max. 2,400 mm up to a maximum total thickness of 6.0 mm.

Additional further processing:

Please ask which further processing options can be implemented for your product. Please use our contact form or make your request by telephone.

Expanded metal - all information

Here you will find all the important information about expanded metal. If you have any questions about your order or questions about individual products, please contact us using the contact form.

What are expanded metal meshes?

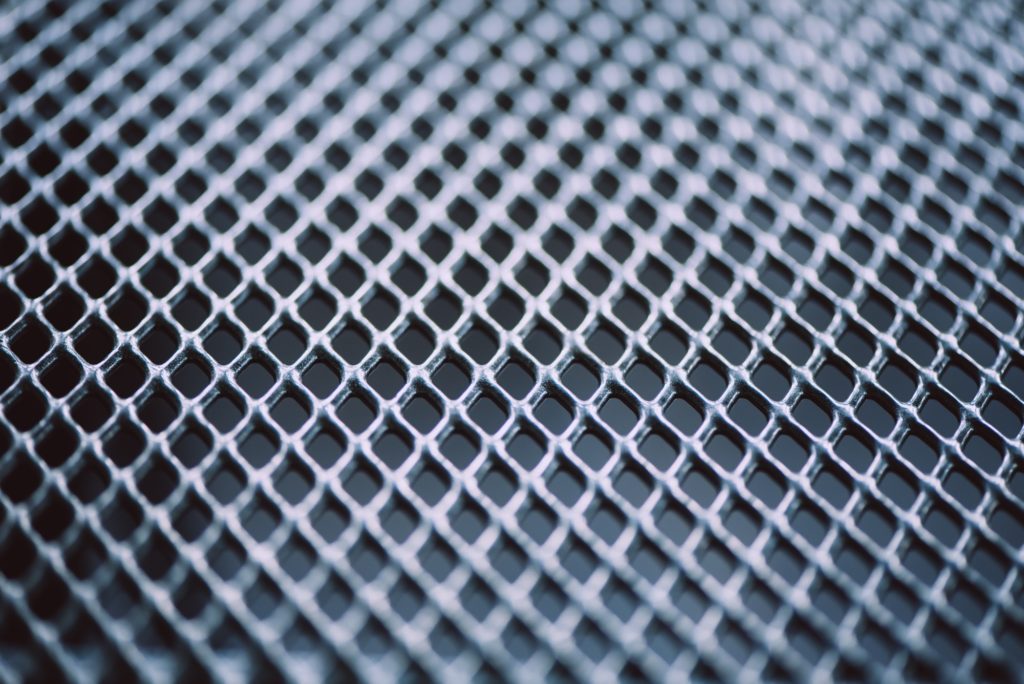

Expanded metalalso known as expanded metal mesh or expanded metal, are made from a single sheet of metal that is formed into a grid-like shape through staggered cuts and simultaneous stretching of the material.

For example, rhombic, square, hexagonal or round meshes can be produced. The special thing about this process is that there is no material waste, which is why Expanded metal is very sustainable and saves resources.

Expanded metal are made of various metals such as stainless steel, aluminum, steel, galvanized and other alloys to meet the specific requirements of different industries.

Its characteristic structure not only offers outstanding strength and durability, but also enables good ventilation and light transmission. Expanded metal also impresses with its aesthetic shapes. These properties make expanded metal mesh a popular Material, which is used in filter and ventilation systems, in security systems and also for decorative purposes.

What are the areas of application for expanded metal mesh?

Expanded metal are used in a wide range of areas and sectors, from industry and architecture to security. Here is an overview of the many possible applications:

Industry:

- Safety covers for machines

- Partition walls in production halls

- Ventilation grilles in air conditioning systems

Construction:

- Façade elements for buildings

- Load-bearing elements in ceiling constructions

- Reinforcing grid in concrete elements

Architecture & Garden:

- Design elements in interior and exterior architecture

- Sun protection grille

- Decorative room dividers

- Garden fences

- Trellis

Security technology:

- Fencing around industrial plants and machinery

- Security doors and window grilles

- Protective grilles for stairs and balconies

Agriculture:

- Grids for animal enclosures and stables

- Components for agricultural machinery

- Protective grids for plants and trees

What are the advantages of expanded metal?

Expanded metal offer a wealth of benefits that make them attractive for a wide range of industrial and design applications.

You want to buy Expanded metal ? See the advantages for yourself:

- High strength: During the manufacturing process, the Material is stretched, giving it enormous stability combined with low weight. Expanded metal can therefore withstand heavy loads.

- Sustainability: The production of expanded metal mesh produces hardly any waste and no Material is wasted. This makes them a particularly resource-saving product.

- Durability: Because expanded metal is made from a single piece of metal, there are no welded seams or joints that can become brittle over time.

- Cost-saving: Due to its durability and low material waste, Expanded metal is extremely cost-saving.

- Corrosion resistance: Expanded metal is highly resistant to corrosion and can even be used in adverse weather conditions. This makes it ideal for use outdoors or in coastal areas.

- Versatility: Expanded metal is available in numerous different mesh shapes and dimensions, so there are almost endless application possibilities.

- Flexibility: Expanded metal mesh is flexible and can be easily formed into a specific size or shape and is characterized by optimal further processing options.

- Good conductivity: Expanded metal has excellent properties as a conductor of electricity.

- Aesthetics: The different mesh types create attractive and aesthetic shapes such as rhombus meshes.

- Permeability: Expanded metal enable excellent air and light permeability and are therefore ideal for ventilation systems or sun protection. At the same time, small mesh sizes enable the filtering and retention of Material.

- Safety: Despite their permeability, Expanded metal offer a high level of safety and protection, making them an ideal choice for barriers, fences and barriers.

What materials are Expanded metal made of?

Expanded metal are mainly made of steel, stainless steel and aluminum. Depending on the intended use, they can then be further processed by hot-dip galvanizing, for example.

- Expanded metal Stainless steel: Due to its corrosion resistance, good workability and durability, stainless steel is ideal for grilles used outdoors or in damp environments. Commonly used types are stainless steel 1.4301, stainless steel 1.4541 and stainless steel 1.4571.

- Expanded metal Steel: Steel, often kept bright, is characterized above all by its high strength and is about 1/3 cheaper than stainless steel. This is why steel grating is often used in the construction industry. Hot-dip galvanized steel is also more resistant to corrosion than untreated steel.

- Expanded metal galvanized: A distinction is made here between pre-galvanized for indoor use and subsequently hot-dip galvanized for outdoor use.

- Expanded metal Aluminum: Aluminum, often used as pure aluminum (AL 99.5), is considered to be corrosion-resistant, easy to form and lightweight. It also has good temperature resistance. Expanded metal mesh made of aluminum is particularly suitable for lightweight constructions.

How are expanded metal meshes produced?

The production of expanded metal mesh begins with metal sheets, usually made of steel, galvanized, stainless steel or aluminium, in thicknesses of 0.5 to 7.0 mm. In the first step, the sheet metal is processed with special cutting tools that make trapezoidal cuts in diamond meshes, for example. These cuts are designed in such a way that the sheet metal is not completely severed between the cuts, but remains expandable.

During the cutting process, the sheet is simultaneously stretched, which leads to an expansion of the cut areas. This process increases the length and therefore also the surface area of the original sheet by a factor of two to twelve, without any loss of material as, unlike perforated sheet production, no waste is produced. The sheet width remains approximately the same.

The process is precisely controlled to create a uniform mesh structure. After the initial cuts, the edges of the sheet are treated to correct distortions and ensure consistent quality across the entire sheet surface. This method enables efficient production of expanded metal with minimal material waste and high material utilization.

Material

Thickness [mm]

Hole type

Perforation-pitch

Dimension [mm]

Throughput

0,00 - 81,00

Results 1 - 20 of 66 are displayed

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 10 x 5 x 2 x 0.8 |

| Weight | 3,4 |

| Dimension | 1000 x 2000 |

| Throughput | 20 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 110 x 42 x 10 x 2 |

| Weight | 5,3 |

| Dimension | 1000 x 2000 |

| Throughput | 52,4 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 6,5 x 1 x 1 |

| Weight | 1,6 |

| Dimension | 1000 x 2000 |

| Throughput | 69 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 8 x 1.5 x 1 |

| Weight | 22 |

| Dimension | 1000 x 2000 |

| Throughput | 6,25 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 3,2 |

| Dimension | 1000 x 2000 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 31 |

| Dimension | 1000 x 2000 |

| Throughput | 61 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 6 x 3 x 1 x 0.5 |

| Weight | 1,7 |

| Dimension | 1000 x 2000 |

| Throughput | 35 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Square mesh |

| Specification | M 10 |

| Weight | 18 |

| Dimension | 1250 x 2500 |

| Throughput | 75 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Square mesh |

| Specification | M 30 |

| Weight | 2,7 |

| Dimension | 1250 x 2500 |

| Throughput | 82 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 10 x 5 x 1.5 x 1 |

| Weight | 5,3 |

| Dimension | 1250 x 2500 |

| Throughput | 37 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 16 x 8 x 1.5 x 1 |

| Weight | 3,3 |

| Dimension | 1250 x 2500 |

| Throughput | 6,25 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 20 x 10 x 2 x 1.5 |

| Weight | 5 |

| Dimension | 1250 x 2500 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 5 |

| Dimension | 1250 x 2500 |

| Throughput | 60 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 4,8 |

| Dimension | 1250 x 2500 |

| Throughput | 61 |

| Material | Aluminum (Al99.5) |

|---|---|

| Wide | 1250 |

| Length | 2500 |

| Mesh form | Diamond mesh |

| Specification | 62 x 25 x 3 x 2 |

| Weight | 4,05 |

| Dimension | 1250 x 2500 |

| Throughput | 76 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 10 x 4.5 x 1 x 0.5 |

| Weight | 3,6 |

| Dimension | 1000 x 2000 |

| Throughput | 55 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 16 x 6,5 x 1 x 1 |

| Weight | 4,9 |

| Dimension | 1000 x 2000 |

| Throughput | 69 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 28 x 10 x 2 x 1.5 |

| Weight | 9,6 |

| Dimension | 1000 x 2000 |

| Throughput | 60 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 4 x 2.2 x 0.5 x 0.5 |

| Weight | 3,6 |

| Dimension | 1000 x 2000 |

| Throughput | 54 |

| Material | Stainless steel 1.4301 |

|---|---|

| Wide | 1000 |

| Length | 2000 |

| Mesh form | Diamond mesh |

| Specification | 42 x 13 x 2.5 x 1.5 |

| Weight | 9,3 |

| Dimension | 1000 x 2000 |

| Throughput | 61 |

Sonic

2024-01-12

Schnelle Lieferung und Material top.

Marc Culas

2023-11-28

Sehr kompetente Beratung - hier wird auf die individuellen Bedürfnisse wirklich eingegangen. Danke & weiter so!

Vicky Moschny

2023-11-13

Absolut Empfehlenswert! Freundliches und kompetentes Personal. Gute Qualität, hervoragender Service und Preis-Leistungsverhältnis. Pünktliche Lieferungen. Vielen Dank und herzliche Grüße an JAERA!

Oscar Casares Solera

2023-11-02

Diese Firma ist einfach herausragend! Ihre Produkte/Dienstleistungen haben meine Erwartungen übertroffen, und die Qualität ist wirklich bemerkenswert. Der Kundenservice ist stets freundlich und äußerst hilfsbereit. Ich kann diese Firma uneingeschränkt empfehlen und werde mit Sicherheit weiterhin ihre Leistungen in Anspruch nehmen. Fünf Sterne sind definitiv verdient!

Andrea S

2023-11-01

Super kompetente Beratung, schnelle Lieferung und erstklassige Qualität. Das Alles zu fairen Preisen.

Jederzeit wieder und sehr zu empfehlen.

Thomas Schäfer

2023-10-31

Haben für unseren Balkon ein Lochblech benötigt, haben gute Beratung und passendes Blech schnell erhalten, empfehlenswert.

Nicolas Holle

2023-10-30

Für meinen Brennstoffhandel (www.holle-premium-holzbrennstoffe.de) habe ich zum Lagerbau von Pellets und Holzbriketts Lochbleche und Gitter benötigt.Der Service, die Lieferung und der Kontakt war hervorragend. Immer wieder gerne. Diese Firma ist zu empfehlen und meine erste Anlaufadresse wenn ich wieder Bleche benötige.

Mariusz Kantor

2023-10-30

Freundlicher Kontakt und Lösungsorientiertes arbeiten.

Google Overall rating 5.0 out of 5 based on 51 reviews